The backbone of countless global industries, from food processing to pharmaceuticals, is a reliable and efficient cooling system. Industrial Refrigeration Equipment represents a complex ecosystem of components designed to remove heat on a massive scale. Unlike domestic units, these systems are engineered for durability, precise temperature control, and continuous operation under demanding conditions. This comprehensive guide delves into the core technologies, critical selection factors, and modern trends, providing essential knowledge for professionals tasked with specifying, maintaining, or upgrading these vital systems.

Understanding the Core Components of an Industrial Refrigeration System

An industrial refrigeration circuit is a sophisticated assembly of key components, each playing a vital role in the heat transfer process. Understanding these parts is the first step in appreciating system design and troubleshooting.

The Heart: Compressors and Condensers

The compressor acts as the system's pump, circulating refrigerant and raising its pressure and temperature.

- Function: Compresses low-pressure, low-temperature refrigerant vapor into high-pressure, high-temperature vapor.

- Common Types: Screw compressors, piston compressors, and scroll compressors, each suited for different capacity ranges and applications.

The condenser then rejects the heat absorbed from the process and added by the compressor to the outside environment.

- Function: Cools and condenses the hot refrigerant vapor from the compressor into a liquid.

- Common Types: Air-cooled, water-cooled, and evaporative condensers.

The Interface: Evaporators and Expansion Devices

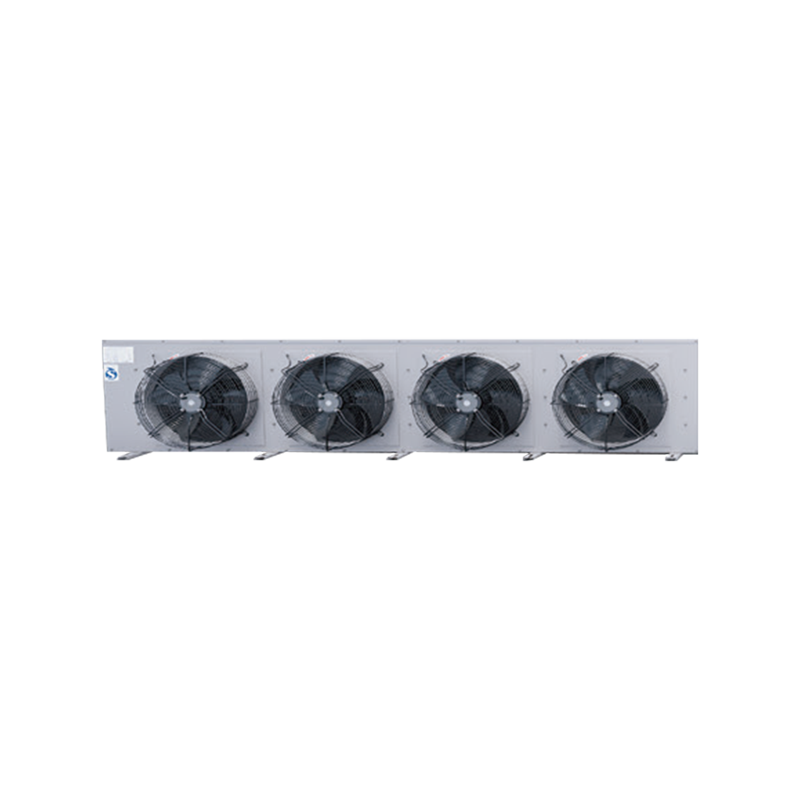

This is where the actual cooling occurs. The evaporator, such as those expertly manufactured by Zhejiang Jinhao Refrigeration Equipment Co., Ltd., absorbs heat from the space or product being cooled.

- Function: The liquid refrigerant expands and evaporates inside the evaporator coils, absorbing immense amounts of heat from its surroundings.

- Design Variations: Include air units (for cold rooms) and liquid chillers (for cooling water/glycol).

The expansion device, often a thermal expansion valve (TXV) or electronic valve, regulates the flow of refrigerant into the evaporator.

- Function: Creates a pressure drop, causing the refrigerant to cool rapidly before entering the evaporator.

- Impact: Precisely controls superheat, optimizing evaporator efficiency.

Key Considerations for Selecting Industrial Refrigeration Equipment

Choosing the right system is not a one-size-fits-all endeavor. It requires a careful analysis of the specific application's needs. This decision-making process directly impacts operational costs, product quality, and system longevity.

Assessing Capacity, Temperature, and Application Needs

The foundational questions revolve around the system's primary duty.

- Required Cooling Capacity (in tons of refrigeration or kW): Calculated based on product load, building envelope, and internal heat generation.

- Target Temperature Range: Blast freezing requires vastly different equipment than chilled water for air conditioning.

- Specific Industry Application: A brewery's needs differ from those of a chemical plant or a distribution warehouse.

Energy Efficiency and Total Cost of Ownership (TCO)

Upfront cost is just one part of the equation. A focus on how to improve energy efficiency in industrial refrigeration systems is crucial for sustainable and profitable operations. Energy is often the largest single operating expense over a system's lifetime.

- Energy Efficiency Ratio (EER) & Coefficient of Performance (COP): Higher numbers indicate better efficiency.

- System Design Philosophy: Considerations like heat recovery, variable speed drives, and advanced controls can drastically cut energy use.

- TCO Analysis: Evaluates initial investment + energy costs + maintenance costs + expected lifespan.

In-Depth Focus: Optimizing Cold Storage and Blast Freezing

Two of the most demanding and common applications for industrial refrigeration are cold storage and blast freezing. Each presents unique challenges that dictate specific equipment choices.

Cold Storage Room Design and Equipment

Designing an efficient cold storage facility goes beyond just installing a large cooler. It involves a holistic approach. For instance, selecting the right cold storage refrigeration unit for warehouse involves matching the evaporator's air throw and defrost method to the room's size, product type, and humidity levels. A common dilemma is choosing between different evaporator types for warehouse applications.

The choice between a forced-air unit and a gravity coil system significantly impacts temperature uniformity and product moisture loss. Forced-air units provide faster pulldown and better air circulation, while gravity coils offer slower, gentler cooling with less dehydration. This comparison can be clearly summarized:

| Feature | Forced-Air Evaporator | Gravity Coil Evaporator |

| Air Circulation | Active, High Velocity | Passive, Natural Convection |

| Temperature Uniformity | Excellent | Good (with proper design) |

| Product Moisture Loss | Higher (if airflow is direct) | Lower |

| Defrost Requirement | More Frequent | Less Frequent |

| Best For | Fast-chilling, high-turnover storage | Long-term storage of sensitive produce |

High-Speed Freezing: Blast Freezer Technology

Blast freezer technology and installation requirements are specialized fields. The goal is to rapidly freeze products through the "heat of fusion" zone to minimize ice crystal formation, which preserves cellular structure and quality. Key requirements include:

- Extreme Capacity: Equipment must handle the massive initial heat load of unfrozen product.

- Very Low Temperatures: Operating at -30°C to -40°C or lower is standard.

- High Air Velocity: Powerful fans ensure maximum heat transfer from product surfaces.

- Robust Construction: Components must withstand thermal stress and frequent defrost cycles.

Maintenance, Troubleshooting, and Modern Innovations

Proactive maintenance is the key to reliability. Furthermore, the industry is rapidly evolving with new technologies aimed at boosting performance and reducing environmental impact.

Ensuring System Longevity and Performance

A robust maintenance regimen prevents costly downtime. Common common problems and solutions for industrial chillers often stem from neglect. Regular tasks include:

- Condenser Cleaning: Dirty condensers increase head pressure, reducing efficiency and capacity.

- Checking Refrigerant Charge: Suboptimal charge levels can cause compressor damage and high energy use.

- Monitoring Oil Levels and Quality: Crucial for compressor health.

- Inspecting Electrical Components: Contactors, relays, and sensors for signs of wear.

Understanding the root cause of frequent issues is vital. For example, high discharge pressure can be caused by a dirty condenser, non-condensable gases, or an overcharge of refrigerant, each requiring a different solution.

The Shift to Natural Refrigerants and Smart Controls

The industry is undergoing a significant green transformation. The move toward natural refrigerants for large-scale industrial cooling like Ammonia (R717), CO2 (R744), and Propane (R290) is driven by environmental regulations (like the F-Gas regulation) and the desire for future-proof, efficient systems [1]. Ammonia, with zero ODP and GWP, remains a highly efficient choice for large facilities despite its toxicity [2].

Simultaneously, the integration of Industrial Internet of Things (IIoT) sensors and advanced controllers allows for predictive maintenance, remote monitoring, and dynamic optimization of system setpoints, leading to substantial energy savings and improved reliability [3].

The Role of Specialized Manufacturers and Suppliers

Navigating this complex landscape is where partnership with a knowledgeable and capable supplier becomes invaluable. A manufacturer that integrates R&D, manufacturing, and application expertise, like Zhejiang Jinhao Refrigeration Equipment Co., Ltd., can provide tailored solutions. As comprehensive Industrial Refrigeration Equipment Suppliers, such companies offer more than just components; they offer system insights, technical support, and custom engineering—such as designing specific Refrigeration Evaporator Equipment for unique applications—ensuring that all elements from the unit series to the finned heat exchanger series work in perfect harmony for optimal performance and longevity.

Frequently Asked Questions (FAQ)

What is the typical lifespan of industrial refrigeration equipment?

With proper design, installation, and a rigorous maintenance program, major components like screw compressors and properly maintained evaporators can last 20-25 years. System longevity is heavily dependent on operating conditions and preventative care.

How often should industrial refrigeration systems undergo professional maintenance?

A minimum of two to four comprehensive professional inspections per year is recommended for most critical systems. Additionally, routine daily or weekly checks by trained facility staff (like checking temperatures and pressures) are essential for early problem detection.

What are the main signs that my industrial chiller needs servicing?

Key warning signs include reduced cooling capacity, unusual noises from the compressor or fans, frequent cycling, higher than normal energy consumption, frost or ice buildup in unusual areas, and fluctuating pressure readings.

Is retrofitting an older system with new, efficient components worthwhile?

Often, yes. Strategic retrofits—such as adding variable speed drives to compressor motors, upgrading to electronic expansion valves, or installing high-efficiency coils—can significantly improve performance and reduce energy costs, extending the system's useful life and providing a strong return on investment.

What are the primary safety considerations for ammonia-based systems?

Ammonia (R717) is toxic and flammable at certain concentrations. Safety is paramount and requires: leak detection systems with alarms, properly designed and ventilated machinery rooms, emergency planning and training for personnel, and compliance with all local and national safety codes like IIAR standards.

References

[1] European Commission. "Regulation (EU) No 517/2014 on fluorinated greenhouse gases." Official Journal of the European Union, 2014. This regulation phases down the use of high-GWP HFCs, driving adoption of natural refrigerants.

[2] Pearson, A. "Ammonia as a Refrigerant." International Journal of Refrigeration, vol. 31, no. 4, 2008, pp. 545-549. This paper reviews the thermodynamic properties and practical applications of ammonia, highlighting its efficiency and environmental profile.

[3] Wang, R., et al. "IoT-based Monitoring and Control for Industrial Refrigeration Systems." Proceedings of the IEEE International Conference on Industrial Technology, 2019. This study demonstrates how IIoT implementation can lead to predictive maintenance and energy savings in refrigeration plants.

English

English русский

русский