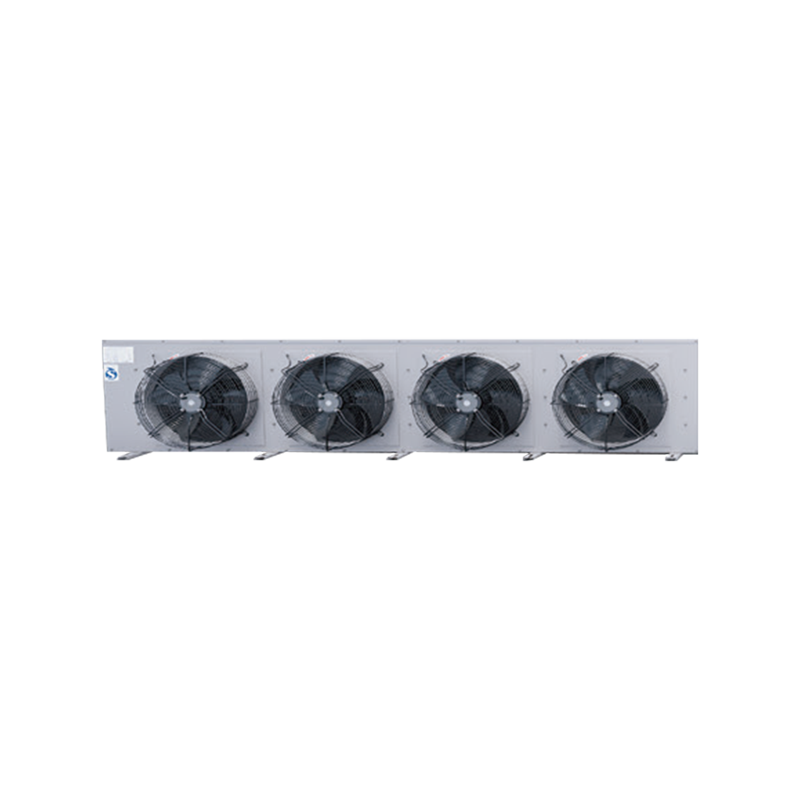

Shell: The structural sheet metal parts are made of high-quality steel plates, and the surfaces are all electrostatically phosphated and sprayed with imported automatic spraying equipment, which has strong corrosion resistance and can adapt to different usage environments.

To ensure good surface quality throughout the service life of the unit. Aluminum or stainless steel shells can be customized according to user needs.

Water tray: designed with a slanted angle to facilitate smooth discharge of defrosting water, avoid floating water, and prevent water accumulation in the water tray.

Heat exchange tube: High high-toothed internally threaded copper tube is selected for high heat transfer efficiency.

Fins: Adopting brand new sine wave hydrophilic aluminum fins, enhancing air disturbance, strengthening heat transfer coefficient, and greatly improving heat transfer performance;

Fan: High static pressure, specially customized high-power external rotor axial flow fan, suitable for high humidity environments, high efficiency, low energy consumption, waterproof and dustproof, with excellent performance; Fan factory

Previously passed static and dynamic balance tests;

Defrosting: Low-power stainless steel defrosting electric heating tubes are selected and arranged uniquely and reasonably, with fast defrosting speed and thorough defrosting, while avoiding heat loss.

Extend the service life of electric heating tubes.

Electrical junction box: The junction box has low temperature resistance, waterproof and dustproof properties, high flame retardancy, and is installed on the front for easy wiring and maintenance.

Fin spacing: The standard spacing is 4.5mm, 6mm, and 9mm; Customizable sheet spacing of 12mm and 18mm to meet user needs.

Refrigerant type: R404A refrigerant can be selected, R507A, R22, R134A, R407C, and R410A can be customized according to user requirements.

Evaporator:

1. The unique tube bundle layout fully considers key issues such as changes in refrigerant state, flow rate, pressure drop, and distribution uniformity under evaporation conditions, resulting in higher heat transfer performance of the evaporator surface cooler;

2. Efficient and compact heat exchanger design, with fork-shaped reinforced heat transfer internal threaded heat exchange tubes;

3. Heat exchange tubes and hydrophilic aluminum fins are mechanically expanded to tightly bond copper tubes with aluminum sheets, in order to achieve optimal heat transfer efficiency.

4. The evaporator's liquid separator and refrigerant circuit have been optimized to ensure optimal efficiency of heat exchange in different application environments.

5. The unique design of the wind deflector is located below the heat exchanger to prevent airflow short circuits.

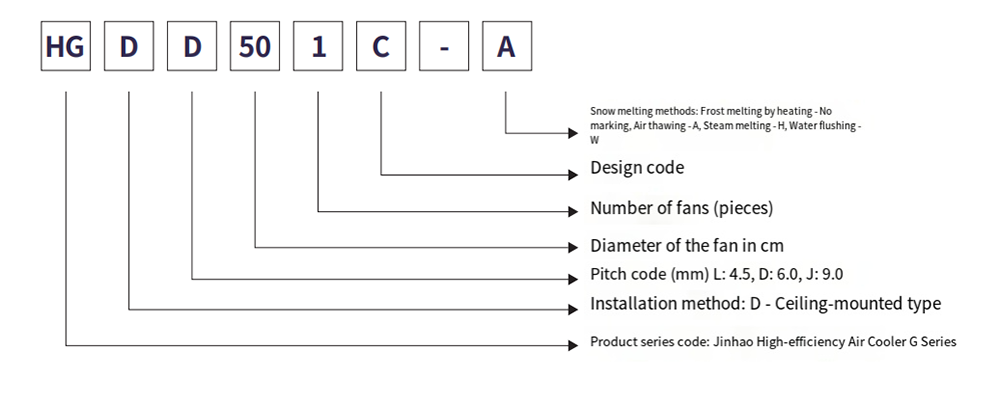

Model Description

Technical parameter table (R404A)

Technical parameters of a high-efficiency air cooler for electric frost ceiling

Film spacing: 4.5mm

|

Model |

Cooling capacity kW |

Tube volume |

Fan parameters |

Snowmelt electric heating |

|||||

|

SC1 |

SC2 |

dm² |

Number of blades x diameter |

Power W |

Air volume m³/h |

Range m |

Coil kW* branch |

Water pan kW*branch |

|

|

HGDL 501C |

6.7 |

4.6 |

3.2 |

1xΦ500 |

1x414 |

5000 |

12 |

0.28*6 |

0.28*2 |

|

HGDL501D |

8.1 |

5.6 |

4.3 |

1xΦ500 |

1x460 |

4900 |

12 |

0.30*6 |

0.30*2 |

|

HGDL 501E |

9.8 |

6.7 |

5.4 |

1xΦ500 |

1x460 |

4500 |

12 |

0.30*8 |

0.30*2 |

|

HGDL601E |

16.6 |

11.4 |

9.2 |

1xΦ600 |

1x780 |

7500 |

15 |

0.40*8 |

0.4*2 |

|

HGDL 502D |

22.2 |

15.3 |

11.8 |

2xΦ500 |

2x460 |

11500 |

13 |

0.72*6 |

0.72*2 |

|

HGDL552D |

25.4 |

17.5 |

13.2 |

2xΦ550 |

2x600 |

13700 |

13 |

0.72*6 |

0.72*6 |

|

HGDL602D |

28.9 |

19.9 |

14.7 |

2xΦ600 |

2x780 |

16500 |

16 |

0.72*10 |

0.72*2 |

|

HGDL602E |

33.8 |

23.3 |

18.4 |

2xΦ600 |

2x780 |

15200 |

16 |

0.72*10 |

0.72*2 |

|

HGDL602F |

37.8 |

26.1 |

22.1 |

2xΦ600 |

2x780 |

14500 |

16 |

0.72*10 |

0.72*2 |

|

HGDL632D |

40.7 |

28.1 |

23.7 |

2xΦ630 |

2x800 |

19000 |

19 |

0.95*10 |

0.95*2 |

|

HGDL632E |

44.1 |

30.4 |

26.9 |

2xΦ630 |

2x800 |

18000 |

19 |

0.87*12 |

0.87*4 |

|

HGDL603F |

54.5 |

37.6 |

32.3 |

3xΦ600 |

3x780 |

20500 |

17 |

1.03*12 |

1.03*4 |

|

HGDL633F |

66.8 |

46.1 |

38.8 |

3xΦ630 |

3x800 |

25500 |

20 |

1.03*14 |

1.03*4 |

Technical parameter table (R404A)

Technical parameters of a high-efficiency air cooler for electric frost ceiling

Film spacing: 6.0mm

|

Model |

Cooling capacity kW |

Tube volume |

Fan parameters |

Snowmelt electric heating |

||||||

|

SC1 |

SC2 |

SC3 |

dm² |

Number of blades x diameter |

Power W |

Air volume m³/h |

Range m |

Coil kW* branch |

Water tray kW*branch |

|

|

HGDD501C |

5.6 |

4.0 |

3.2 |

3.2 |

1xΦ500 |

1x414 |

5200 |

12 |

0.28*8 |

0.28*2 |

|

HGDD501D |

7.1 |

5.1 |

4.0 |

4.3 |

1xΦ500 |

1x460 |

5100 |

12 |

0.30*8 |

0.30*2 |

|

HGDD501E |

82 |

5.9 |

4.6 |

5.4 |

1xΦ500 |

1x460 |

4800 |

12 |

0.30*10 |

0.30*2 |

|

HGDD601E |

14.4 |

10.3 |

8.1 |

9.2 |

1xΦ600 |

1x780 |

8200 |

15 |

0.40*10 |

0.4*2 |

|

HGDD502D |

183 |

13.1 |

10.3 |

11.8 |

2xΦ500 |

2x460 |

12000 |

13 |

0.72*8 |

0.72*2 |

|

HGDD552D |

21.8 |

15.1 |

11.9 |

13.2 |

2xΦ550 |

2x600 |

14500 |

13 |

0.72*8 |

0.72*6 |

|

HGDD602D |

24.1 |

17.2 |

13.6 |

14.7 |

2xΦ600 |

2x780 |

17000 |

16 |

0.72*12 |

0.72*2 |

|

HGDD602E |

29.1 |

20.8 |

164 |

18.4 |

2xΦ600 |

2x780 |

16400 |

16 |

0.72*12 |

0.72*2 |

|

HGDD602F |

32.1 |

22.9 |

18.1 |

22.1 |

2xΦ600 |

2x780 |

15500 |

16 |

0.72*12 |

0.72*2 |

|

HGDD632D |

33.7 |

24.1 |

19.0 |

23.7 |

2xΦ630 |

2x800 |

20000 |

19 |

0.95*12 |

0.95*2 |

|

HGDD632E |

37.2 |

26.6 |

21.0 |

26.9 |

2xΦ630 |

2x800 |

19000 |

19 |

0.87*12 |

0.87*4 |

|

HGDD603F |

46.8 |

33.4 |

264 |

32.3 |

3xΦ600 |

3x780 |

22000 |

17 |

1.03*12 |

1.03*4 |

|

HGDD633F |

56.7 |

40.5 |

32.0 |

38.8 |

3xΦ630 |

3x800 |

26500 |

20 |

1.03*14 |

1.03*4 |

Technical parameter table (R404A)

Technical parameters of a high-efficiency air cooler for electric frost ceiling

Film spacing: 9.0mm

|

Model |

Cooling capacity kW |

Tube volume |

Fan parameters |

Snowmelt electric heating |

||||||

|

SC3 |

SC4 |

SC5 |

dm² |

Number of blades x diameter |

Power W |

Air volume m³/h |

Range m |

Coil kW* branch |

Water tray kW*branch |

|

|

HGDJ501C |

2.5 |

2.0 |

1.9 |

3.2 |

1xΦ500 |

1x414 |

5300 |

12 |

0.28*8 |

0.28*2 |

|

HGDJ501D |

3.3 |

2.6 |

2.5 |

4.3 |

1xΦ500 |

1x460 |

5500 |

12 |

0.30*8 |

0.30*2 |

|

HGDJ501E |

3.7 |

3.0 |

2.9 |

5.4 |

1xΦ500 |

1x460 |

5100 |

12 |

0.30*10 |

0.30*2 |

|

HGDJ601E |

6.5 |

5.2 |

5.0 |

9.2 |

1xΦ600 |

1x780 |

8300 |

15 |

0.40*10 |

0.4*2 |

|

HGDJ502D |

8.3 |

6.6 |

6.3 |

11.8 |

2xΦ500 |

2x460 |

12500 |

13 |

0.72*8 |

0.72*2 |

|

HGDJ552D |

8.7 |

6.9 |

6.7 |

13.2 |

2xΦ550 |

2x600 |

15000 |

13 |

0.72*8 |

0.72*6 |

|

HGDJ602D |

10.8 |

8.5 |

7.8 |

14.7 |

2xΦ600 |

2x780 |

17500 |

16 |

0.72*12 |

0.72*2 |

|

HGDJ602E |

13.3 |

10.6 |

10.2 |

18.4 |

2xΦ600 |

2×780 |

17000 |

16 |

0.72*12 |

0.72*2 |

|

HGDJ602F |

14.5 |

11.6 |

11.1 |

22.1 |

2xΦ600 |

2x780 |

16000 |

16 |

0.72*12 |

0.72*2 |

|

HGDJ632D |

15.8 |

12.6 |

12.1 |

23.7 |

2xΦ630 |

2x800 |

21000 |

19 |

0.95*12 |

0.95*2 |

|

HGDJ632E |

17.7 |

14.1 |

13.5 |

26.9 |

2xΦ630 |

2x800 |

20500 |

19 |

0.87*12 |

0.87*4 |

|

HGDJ603F |

21.4 |

17.1 |

16.4 |

32.3 |

3xΦ600 |

3x780 |

23000 |

17 |

1.03*12 |

1.03*4 |

|

HGDJ633F |

25.4 |

20.3 |

19.5 |

38.8 |

3xΦ630 |

3x800 |

27000 |

20 |

1.03*14 |

1.03*4 |

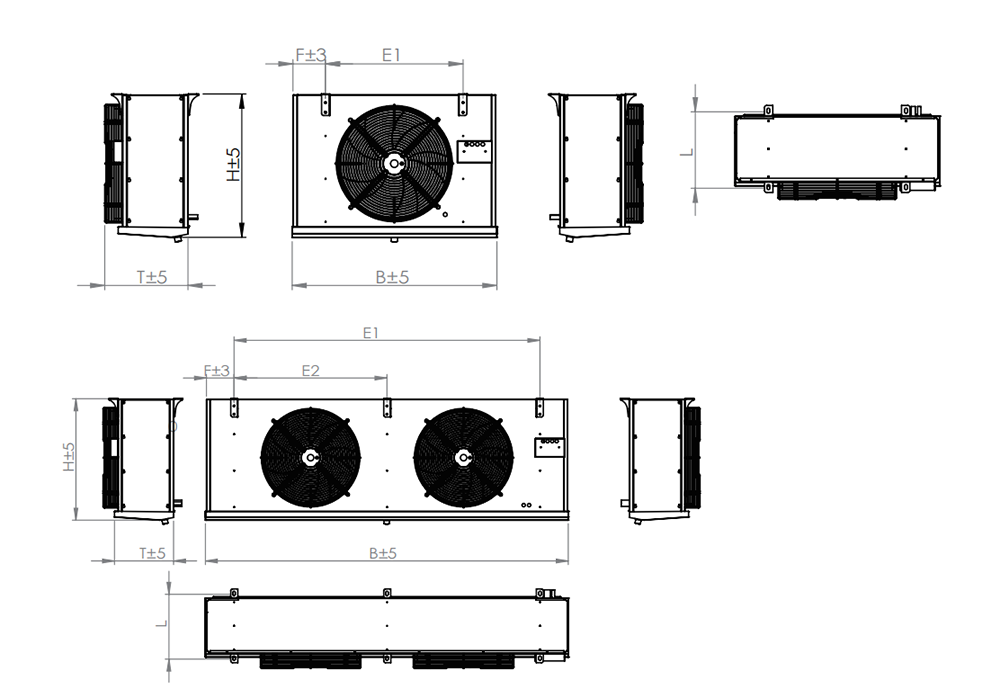

Appearance and installation dimensions

Appearance and installation dimensions of a high-efficiency electric frost ceiling air cooler

Film spacing: 4.5mm

|

Model |

Interface Specification(mm) |

Dimensions B*T*H |

Installation dimensions |

weight |

Outline map markup |

|||||

|

Inlet/return tube |

Drainage/(inch) |

LxWxH(mm) |

L |

E1 |

E2 |

E3 |

F |

medical history |

||

|

HGDL501C |

Φ12/Φ22 |

G3/4 |

952*400*674 |

340 |

640 |

/ |

/ |

126 |

36 |

A |

|

HGDL501D |

Φ12/Φ22 |

G3/4 |

952*400*674 |

340 |

640 |

/ |

/ |

126 |

38 |

A |

|

HGDL501E |

Φ12/Φ22 |

G1 |

952*490*674 |

430 |

640 |

/ |

/ |

126 |

44 |

A |

|

HGDL601E |

Φ16/Φ28 |

G1 |

1172*490*831 |

430 |

860 |

/ |

/ |

126 |

56 |

A |

|

HGDL502D |

Φ16/Φ35 |

G1 |

1992*400*680 |

340 |

840 |

840 |

/ |

126 |

80 |

B |

|

HGDL552D |

Φ16/Φ35 |

G1 |

1992*400*760 |

340 |

840 |

840 |

/ |

126 |

85 |

B |

|

HGDL602D |

Φ22/Φ42 |

G1-1/2 |

1992*400*831 |

340 |

840 |

840 |

/ |

126 |

95 |

B |

|

HGDL602E |

Φ22/Φ42 |

G1-1/2 |

1992*490*831 |

430 |

840 |

840 |

/ |

126 |

115 |

B |

|

HGDL602F |

Φ22/Φ42 |

G1-1/2 |

1992*490*831 |

430 |

840 |

840 |

/ |

126 |

125 |

B |

|

HGDL632D |

Φ22/Φ42 |

G1-1/2 |

2552*400*984 |

340 |

1120 |

1120 |

/ |

126 |

144 |

B |

|

HGDL632E |

Φ22/Φ42 |

G1-1/2 |

2352*490*984 |

430 |

1020 |

1020 |

/ |

126 |

160 |

B |

|

HGDL603F |

Φ25/Φ50 |

G1-1/2 |

2751*490*831 |

430 |

813 |

813 |

813 |

126 |

166 |

C |

|

HGDL633F |

Φ25/Φ50 |

G2 |

2751*490*984 |

430 |

813 |

813 |

813 |

126 |

196 |

C |

Appearance and installation dimensions

Appearance and installation dimensions of a high-efficiency electric frost ceiling air cooler

Film spacing: 6.0mm

|

Model |

Interface Specification(mm) |

Dimensions B*T*H |

Installation dimensions |

weight |

Outline map markup |

|||||

|

Inlet/return tube |

Drainage/(inch) |

LxWxH(mm) |

L |

E1 |

E2 |

E3 |

F |

medical history |

||

|

HGDD5011C |

Φ12/Φ22 |

G3/4 |

952*400*674 |

340 |

640 |

/ |

/ |

126 |

35 |

|

|

HGDD50i¹D |

Φ12/Φ22 |

G3/4 |

952*400*674 |

340 |

640 |

/ |

/ |

126 |

37 |

|

|

HGDD501E |

Φ12/Φ22 |

G1 |

952*490*674 |

430 |

640 |

/ |

/ |

126 |

43 |

|

|

HGDD60i¹E |

Φ16/Φ28 |

G1 |

1172*490*831 |

430 |

860 |

/ |

/ |

126 |

57 |

A |

|

HGDD502D |

Φ16/Φ35 |

G1 |

1992*400*680 |

340 |

840 |

840 |

/ |

126 |

78 |

B |

|

HGDD552D |

Φ16/Φ35 |

G1 |

1992*400*760 |

340 |

840 |

840 |

/ |

126 |

86 |

B |

|

HGDD602D |

Φ22/Φ42 |

G1-1/2 |

1992*400*831 |

340 |

840 |

840 |

/ |

126 |

93 |

B |

|

HGDD602E |

Φ22/Φ42 |

G1-1/2 |

1992*490*831 |

430 |

840 |

840 |

/ |

126 |

112 |

B |

|

HGDD602F |

Φ22/Φ42 |

G1-1/2 |

1992*490*831 |

430 |

840 |

840 |

/ |

126 |

122 |

B |

|

HGDD632D |

Φ22/Φ42 |

G1-1/2 |

2552*400*984 |

340 |

1120 |

1120 |

/ |

126 |

140 |

B |

|

HGDD632E |

Φ22/Φ42 |

G1-1/2 |

2352*490*984 |

430 |

1020 |

1020 |

/ |

126 |

154 |

B |

|

HGDD603F |

Φ25/Φ50 |

G1-1/2 |

2751*490*831 |

430 |

813 |

813 |

813 |

126 |

162 |

G |

|

HGDD633F |

Φ25/Φ50 |

G2 |

2751*490*984 |

430 |

813 |

813 |

813 |

126 |

192 |

C |

Appearance and installation dimensions

Appearance and installation dimensions of a high-efficiency electric frost ceiling air cooler

Film spacing: 9.0mm

|

Model |

Interface Specification(mm) |

Dimensions B*T*H |

Installation dimensions |

weight |

Outline map markup |

|||||

|

Inlet/return tube |

Drainage/(inch) |

LxWxH(mm) |

L |

E1 |

E2 |

E3 |

F |

medical history |

||

|

HGDJ501C |

Φ12/Φ22 |

G3/4 |

952*400*674 |

340 |

640 |

/ |

/ |

126 |

34 |

|

|

HGDJ501D |

Φ12/Φ22 |

G3/4 |

952*400*674 |

340 |

640 |

/ |

/ |

126 |

36 |

|

|

HGDJ501E |

Φ12/Φ22 |

G1 |

952*490*674 |

430 |

640 |

/ |

/ |

126 |

42 |

|

|

HGDJ601E |

Φ16/Φ28 |

G1 |

1172*490*831 |

430 |

860 |

/ |

/ |

126 |

55 |

A |

|

HGDJ502D |

Φ16/Φ35 |

G1 |

1992*400*680 |

340 |

840 |

840 |

/ |

126 |

76 |

B |

|

HGDJ552D |

Φ16/Φ35 |

G1 |

1992*400*760 |

340 |

840 |

840 |

/ |

126 |

87 |

B |

|

HGDJ602D |

Φ22/Φ42 |

G1-1/2 |

1992*400*831 |

340 |

840 |

840 |

/ |

126 |

94 |

B |

|

HGDJ602E |

Φ22/Φ42 |

G1-1/2 |

1992*490*831 |

430 |

840 |

840 |

/ |

126 |

114 |

B |

|

HGDJ602F |

Φ22/Φ42 |

G1-1/2 |

1992*490*831 |

430 |

840 |

840 |

/ |

126 |

121 |

B |

|

HGDJ632D |

Φ22/Φ42 |

G1-1/2 |

2552*400*984 |

340 |

1120 |

1120 |

/ |

126 |

139 |

B |

|

HGDJ632E |

Φ22/Φ42 |

G1-1/2 |

2352*490*984 |

430 |

1020 |

1020 |

/ |

126 |

160 |

B |

|

HGDJ603F |

Φ25/Φ50 |

G1-1/2 |

2751*490*831 |

430 |

813 |

813 |

813 |

126 |

162 |

C |

|

HGDJ633F |

Φ25/Φ50 |

G2 |

2751*490*984 |

430 |

813 |

813 |

813 |

126 |

190 |

C |

Note 1: Design Standards:

|

Standard heat transfer conditions |

Inlet air temperature |

Evaporation temperature |

Relative temperature |

Relative temperature |

Superheat |

|

SC1 |

10℃ |

0℃ |

85% |

1.35 |

6.5K |

|

SC2 |

0℃ |

-8℃ |

85% |

1.15 |

5.2K |

|

SC3 |

-18℃ |

-25℃ |

95% |

1.05 |

4.6K |

|

SC4 |

-25℃ |

-31℃ |

95% |

1.01 |

3.9K |

|

SC5 |

-34℃ |

-40℃ |

95% |

1.01 |

3.9K |

Note 2: Conversion factor for refrigerant

|

Refrigerants |

Operating conditions |

R22 |

R404A |

R507 |

R134a |

|

Correction factor |

SC1 |

0.95 |

1 |

1 |

0.93 |

|

Correction factor |

SC2 |

0.95 |

1 |

1 |

0.91 |

|

Correction factor |

SC3 |

0.95 |

1 |

1 |

0.85 |

English

English русский

русский