Product Introduction

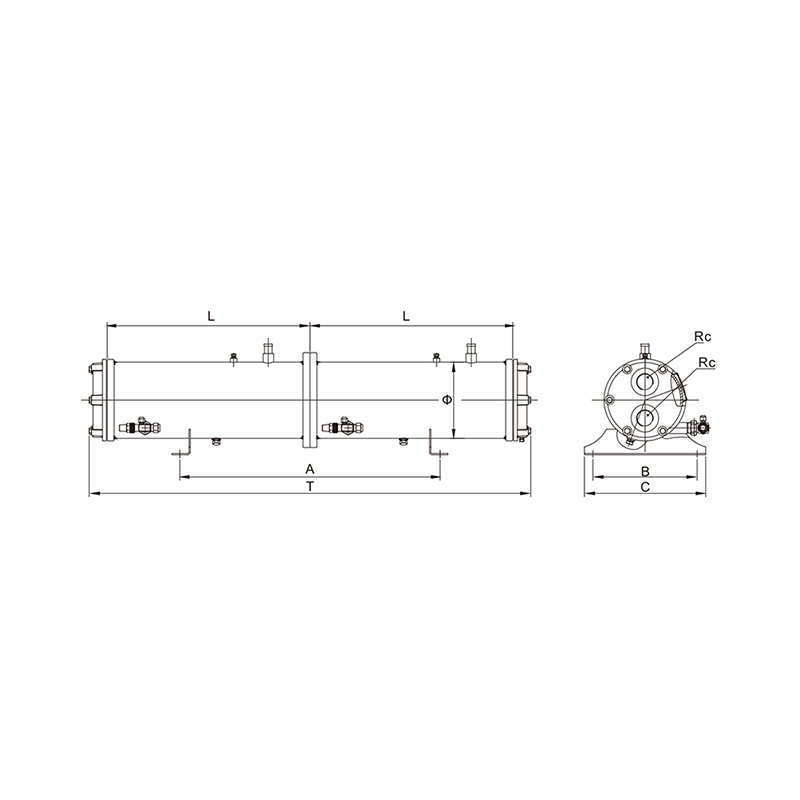

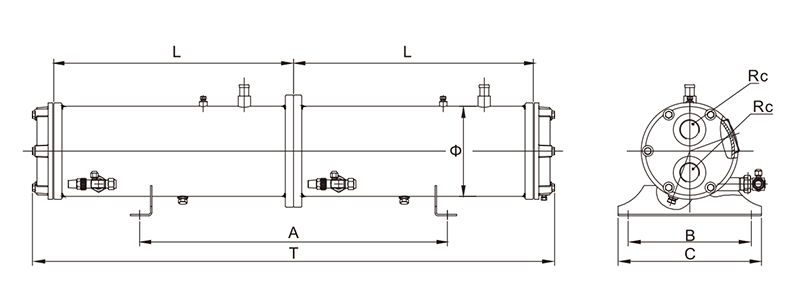

The dual-system shell and tube water-cooled condenser is the core heat exchange equipment of the refrigeration system, specially designed for high-load scenarios such as industrial cold storage, central air conditioning, water chillers, and chemical cooling. It adopts a composite structure of high-strength seamless steel pipes and TP2 hard copper tubes. Through a precise tube expansion process, the shell and tube are closely adhered. The heat transfer efficiency is increased by more than 30% compared with traditional designs, significantly shortening the condensation time of the refrigerant. The dual-loop design supports independent or coordinated operation, which can flexibly match the requirements of different working conditions, especially suitable for high-capacity refrigeration or efficient heat dissipation in high-temperature environments.

The condenser is equipped with built-in spiral deflector plates to optimize the water flow path. Combined with an efficient cooling water circulation system, it can quickly remove heat and ensure the stable operation of the unit. The shell undergoes triple anti-corrosion treatments of acid washing, phosphating, and passivation, which make it highly resistant to corrosion, suitable for various water quality environments, and extends the service life of the equipment. The double-end covers are connected by flanges and equipped with high-precision sealing gaskets. They have passed the 2.6MPa air tightness test, eliminating the risk of leakage. The modular structure supports vertical or horizontal installation, saves space, and is easy to maintain, making it an ideal choice for the efficient and reliable operation of refrigeration systems.

English

English русский

русский